Why Us |

:: Most comprehensive range of riveting machines in the industry.

:: Streamlined design for extended machine & tool life under rugged conditions.

:: Consistent high quality results, even with minimum operator skills. Simple tools, low tool costs.

:: User friendly riveting machines that are easy to maintain.

:: Assurance towards risk & damage to the critical parts of machinery. Special customization of products.

Orbital Riveting |

Orbital Systems, a specialist in riveting, is known to manufacturing & export robust and sound quality riveting machines. Innovative concept & modern manufacturing techniques ensure that our riveting machines are precision engineered & perform with consistent repeatability.

Types of Riveting Machines |

. Spin Riveting Machine

. Dual Head Riveting Machine

. Multi Spindle Head Riveting Machine

. Multi Point Riveting Machine

. Modular Units

. Special Purpose Machine

Tour of Factory |

Your chance to acquaint with our state-of-the-art infrastructure. Spread in a area of 1600 sq.mtr, this factory can be compared with the best in the world. Facilities, machines, technology, research, procedures and work culture everything truly world class.

Applications |

Stepless adjustment of riveting force’ time, stroke and speed allows the machine to perform on a wide variety of application. The machine can be used for a range of jobs from freely swiveling joints to clamped, torque resisting joints.

Features |

:: Micromatic stop allows stepless and precise adjustment of stroke length

:: Rigid construction

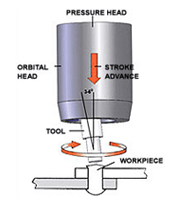

:: Precise orbital motion

:: Easy to service and maintain

:: Standard accessories include digital time control

Models |

Riveting capacity (M.S. 38 Kg/mm2 U.T.S) |

Throat depth |

Shut height (Max) |

Stroke adjustable |

Cycle time adjustable |

Over all dimension (mm) |

Motor 3Ø415V |

Air pressure |

Model-003 |

3 mm |

110 mm |

200 mm |

0-30 mm |

0-9.9 Sec. |

470x400x860 |

0.25HP(0.18Kw) |

3-7 Kg/cm 2 |

Model-005 |

6 mm |

110 mm |

180 mm |

0-30 mm |

0-9.9Sec. |

470x400x890 |

0.5 HP (0.37 Kw) |

3-7 Kg/cm 2 |

Model-008 |

8 mm |

140 mm |

225 mm |

0-45 mm |

0-9.9Sec. |

570x525x1100 |

1 HP(0.75Kw) |

3-7 Kg/cm 2 |

Model-012 |

12 mm |

200 mm |

280 mm |

0-45 mm |

0-9.9Sec. |

625x585x1325 |

1.5HP (1.2Kw) |

3-7Kg/cm 2 |

Model-012H |

12 mm |

200 mm |

280 mm |

0-45 mm |

0-9.9Sec. |

625x585x1325 |

3.5HP (2.7Kw) |

10-50Kg/cm 2 |

Model-016-H |

16 mm |

225 mm |

220 mm |

0-45 mm |

0-9.9 Sec. |

540x615x1375 |

6.0HP (4.5Kw) |

0-80 Kg/cm 2 (Hydraulic Pressure) |

Advantages |

:: Long tool life

:: Low axial thrust

:: Gentle deformation

:: Simple tooling and easy setup

:: Least distortion of parent material

:: Fast operation

:: Noiseless operation

:: Protects fragile parts

:: Precise control on riveting process

Optional Accessories |

:: Machine stand or floor mounting

:: Special tooling to reach inaccessible parts

:: Tool locking devices for notching / marking operation

:: Pressure pad to hold down the assembly during riveting

:: Carbide tipped form tools for materials that are difficult to rivet

:: PLC based controls